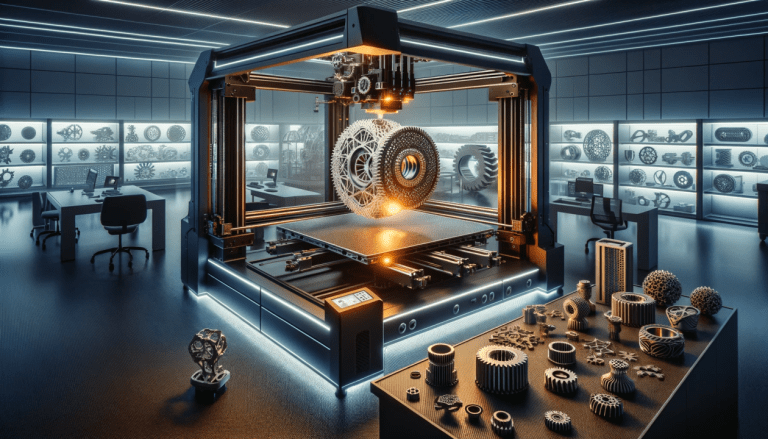

Because of developments in modeling techniques and software capabilities, it is now possible to produce detailed and sophisticated designs with 3D printing. While beginners may begin with simple forms and structures, seasoned enthusiasts and experts progress to more complex creations, pushing the frontiers of creativity and innovation. In this blog post, we’ll look at some of the advanced techniques required for mastering complicated 3D print modelling.

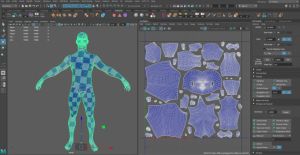

Models based on constraints and parameters are created using the effective technique known as parametric modeling. Through the definition of variables like dimensions, angles, and component interactions, designers may effortlessly adjust and modify their designs to satisfy particular requirements. This technique works especially well for constructing complicated patterns and complex geometries with accurate measurements.

Generative Design: Generative design leverages algorithms to produce a large number of design iterations according to predetermined parameters and objectives, drawing inspiration from nature’s optimization processes. Through the process of modeling multiple scenarios and evaluating the outcomes of every iteration, designers are able to find creative and effective answers to challenging issues. This method works incredibly well for making lightweight structures with specialized functionalities, complex lattices, and organic shapes.

Optimizing the distribution of materials within a design to maximize performance while reducing weight and material consumption is known as topology optimization. Designers are able to produce structurally sophisticated components that are lightweight and economical by repeatedly dispersing loads and eliminating extra material. The aerospace, automotive, and architectural sectors frequently use this process to create high-performance parts with little material waste.

Multi-Part Assemblies and Interlocking Mechanisms: Assemblies with several components that fit together perfectly are frequently needed for complex designs. Designers can guarantee exact alignment and secure assembly without the need for additional hardware by utilizing interlocking mechanisms like tabs, slots, and snap-fit connectors. By carefully designing each component to complement the others, designers can create intricate assemblies that are both functional and visually appealing.

Support Structure Optimization: To avoid print failures, support structures are required when printing intricate patterns with overhangs and unsupported parts. Excessive support material, however, might add to post-processing work, material consumption, and print time. Sophisticated methods, like personalized support structure design and automatic support generation algorithms, help maximize print quality by optimizing support location and reducing material waste.

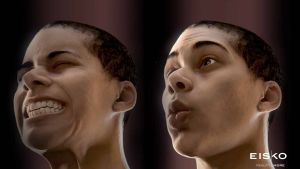

Surface Finishing & Post-Processing: Careful post-processing methods are frequently necessary to attain a perfect finish on intricate 3D printing. Surface treatments such as painting, sanding, polishing, and applying coatings can improve the printed parts’ functional performance and visual appeal. Furthermore, cutting-edge post-processing techniques like dyeing, vapor smoothing, and electroplating present special chances to alter the features and seem of 3D-printed goods.

To sum up, mastering intricate 3D print modeling necessitates a blend of sophisticated methods, original problem-solving, and meticulous attention to detail. Through the utilization of cutting-edge techniques such as parametric modeling, generative design, topology optimization, and others, designers may expand the potential of 3D printing technology and achieve unprecedented results. The process of learning to create complex ideas is just as fulfilling as the finished product, whether it’s detailed works of art, useful prototypes, or architectural wonders.